Neutrons play a definitive role in our understanding of the material world. They allow scientists to look inside the structure of matter, showing where atoms are and what atoms do. The unique capabilities of neutron scattering techniques have already attracted the attention of industrial and applied scientists. The mission of the Shull Wollan Center Industrial Applications Program (IAP) is to promote industry engagement with two of the most powerful neutron science facilities in the world—the High Flux Isotope Reactor and the Spallation Neutron Source, located at Oak Ridge National Laboratory and sponsored by the US Department of Energy Office of Science, Scientific User Facilities.

Why Use Neutrons?

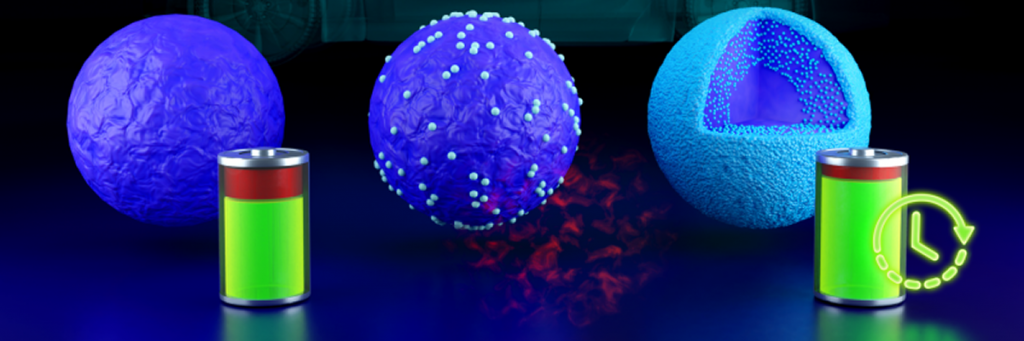

Our technology and our economy require increasingly complex materials with specialized properties. Neutron scattering plays a central role in probing the key properties of new materials critical to advances in energy, nanotechnology, and communication.

The unique capabilities of neutron scattering techniques have already attracted the attention of industrial and applied scientists to solve diverse and challenging problems across a wide range of sectors.

Neutron imaging has powerful applications in additive manufacturing where neutron-computed tomography data can be quantitatively compared with engineering drawings, i. e., to study the internal structure of turbine blades. The “penetrating power” of neutrons offers unique opportunities for non-destructive testing on an atomic scale to investigate residual stress, deformation, and microstructure of engineering components often under their in-service operating conditions of load and/or high temperature.

Neutron scattering provides essential information at the atomic and molecular level that is used to further product development and understand the performance of new materials. These include, but are not limited to: clean technology products such as fuel cell and battery materials; magnets, multiferroics and data storage devices; superconductors; catalysts and molecular sieves; polymers and surfactants.

Neutron scattering techniques are highly complementary to computational techniques such as molecular dynamics simulations and finite element calculations of strains and stresses. Modeling and simulation have an important role in benchmarking and the verification of analytical developments in these areas.

For further information visit ORNL Neutron Sciences For Industry.